Stainless steel is a term that refers to a group of iron-based metal alloys that contain a minimum of approximately 10.5% chromium. The presence of chromium creates an invisible surface film of chromium oxide which prevents iron from rusting and also provides the unique luster and strength of stainless steel. Other elements, like nickel, molybdenum, or carbon, may be added to enhance specific properties. Due to its resistance to rust, corrosion, and staining, stainless steel is often used in kitchenware, surgical instruments, building materials, and various other industrial applications.

Materials LoboStar Uses

We take pride in harnessing the finest materials the market offers, guaranteeing product excellence and endurance. Our adept engineering and manufacturing maestros meticulously choose each material, aligning perfectly with every project's unique specifications.

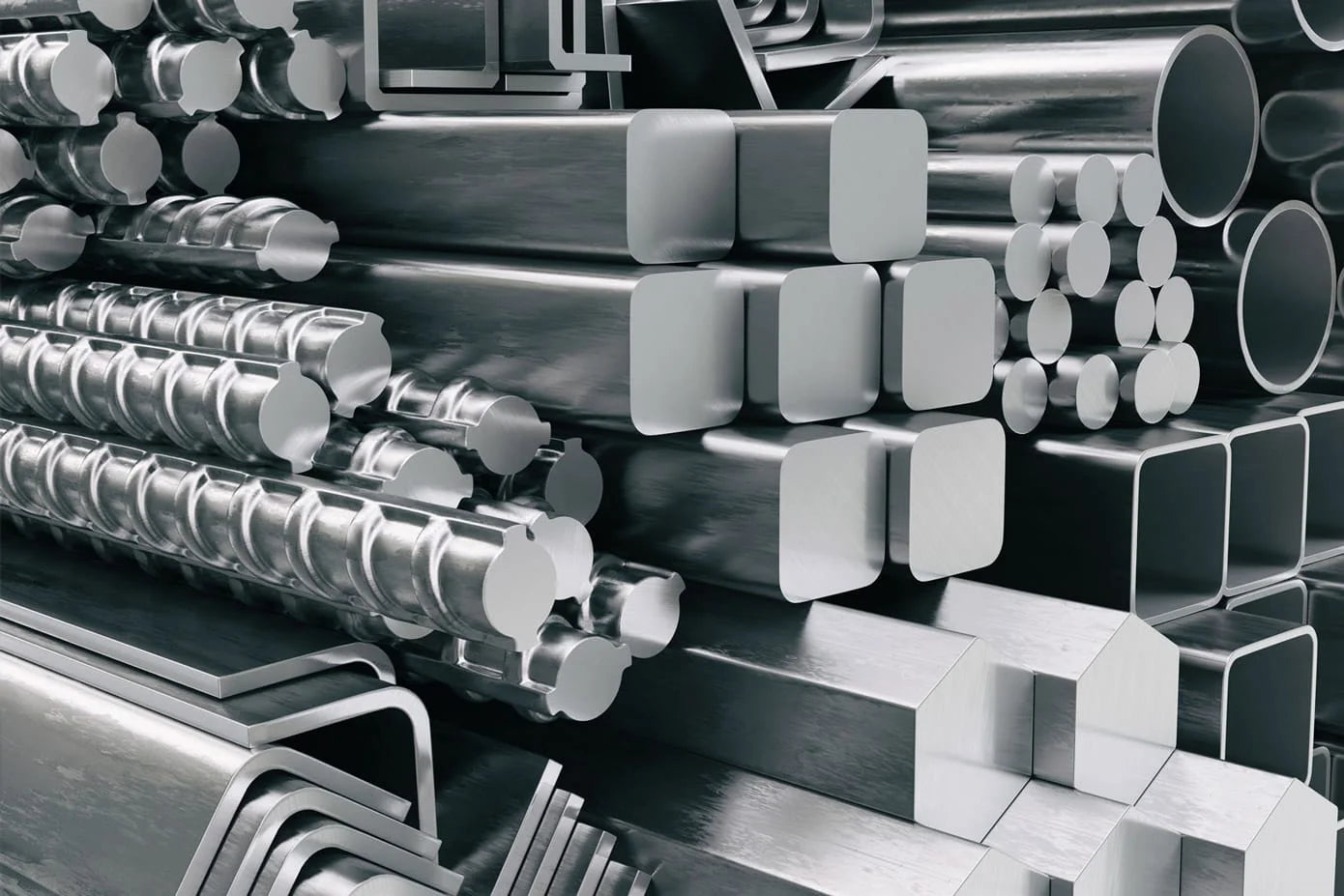

Steel

Steel, an eloquent blend of iron and carbon, is renowned for its formidable strength, enduring hardness, and exceptional toughness. Its industry-wide acclaim stems from its unmatched versatility and adaptability. By introducing other elements, steel can be tailored to amplify specific traits, like combatting corrosion or enhancing weldability. From towering skyscrapers and majestic bridges to nimble automobiles and precision tools, steel forms the backbone of our modern world.

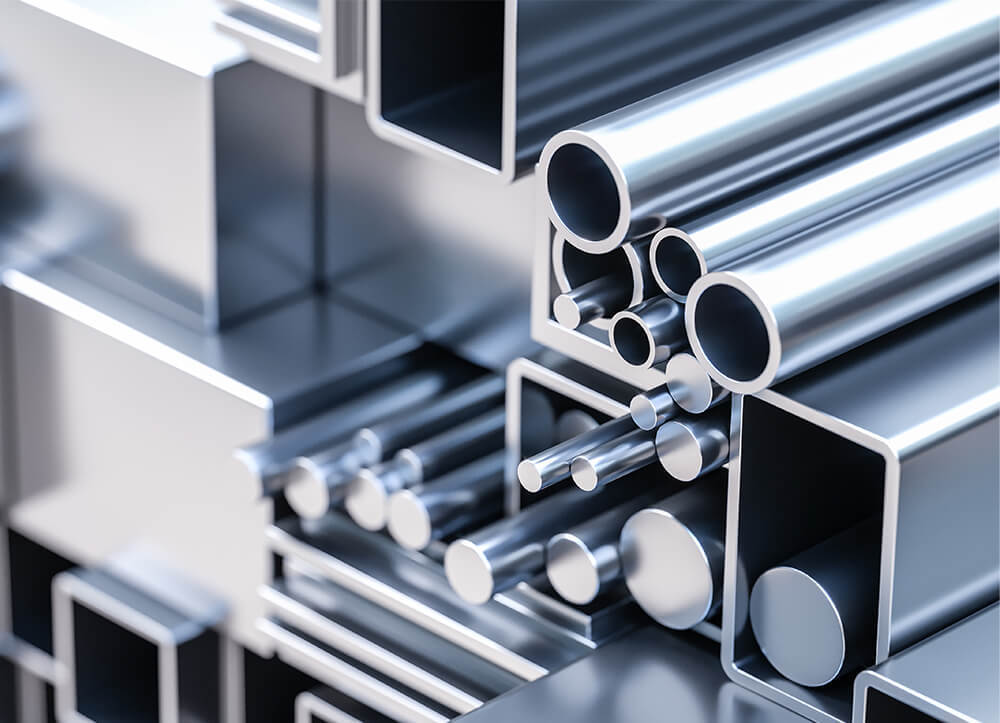

Aluminum

Aluminum, a feather-light yet robust metal nestled within the Earth's crust, graces our daily lives, from beverage cans and culinary tools to window architectures and automobile components. Beyond its vast applications, its recyclable nature champions eco-friendliness, conserving energy and curbing environmental impact.

We work both in sheet and tubing.

Brass

Brass is a metal alloy composed primarily of copper and zinc, although it can also contain small amounts of other elements such as lead, tin, or aluminum, depending on the specific alloy composition. The proportion of copper to zinc in brass can vary, resulting in different types of brass with varying properties. Brass is known for its attractive yellowish-gold color and is widely used in various applications due to its desirable characteristics, including corrosion resistance, malleability, and conductivity. It is commonly used in the production of musical instruments, plumbing fixtures, decorative items, ammunition casings, and various mechanical and electrical components. The specific properties of brass alloys can be tailored to suit different purposes by adjusting the alloy composition.

We work both in sheet and tubing.

Bronze

Bronze is a metal alloy primarily composed of copper and tin, although other elements like aluminum, manganese, and nickel may be included in varying proportions. The exact composition of bronze can vary depending on its intended use, but typically, it contains around 90% copper and 10% tin.

Bronze is known for its distinctive reddish-brown color and has been used for thousands of years in various applications, including sculpture, tools, weapons, musical instruments, and decorative items. It is valued for its durability, corrosion resistance, and malleability, making it a versatile material for a wide range of artistic, industrial, and practical purposes. Bronze alloys can exhibit different characteristics and properties depending on the specific metals added and their proportions, which allows for customization to suit specific requirements.

We work both in sheet and tubing.